Hey, do you want to know something really cool?

We are making the most sustainable anode graphite for EVs to enable the green mobility transition.

In 2024, the planet’s average temperature for the first time soared past the 1.5 degrees °C threshold above pre industrial levels - a line scientists warned we should never cross.

Dramatic consequences from global warming caused by greenhouse gas emissions are already visible on a regular basis.

Transport alone accounts for 20% of the world’s total annual CO₂ emissions.

SourceTo fight climate change, we urgently need to decarbonize.

The shift to electromobility is part of the solution.

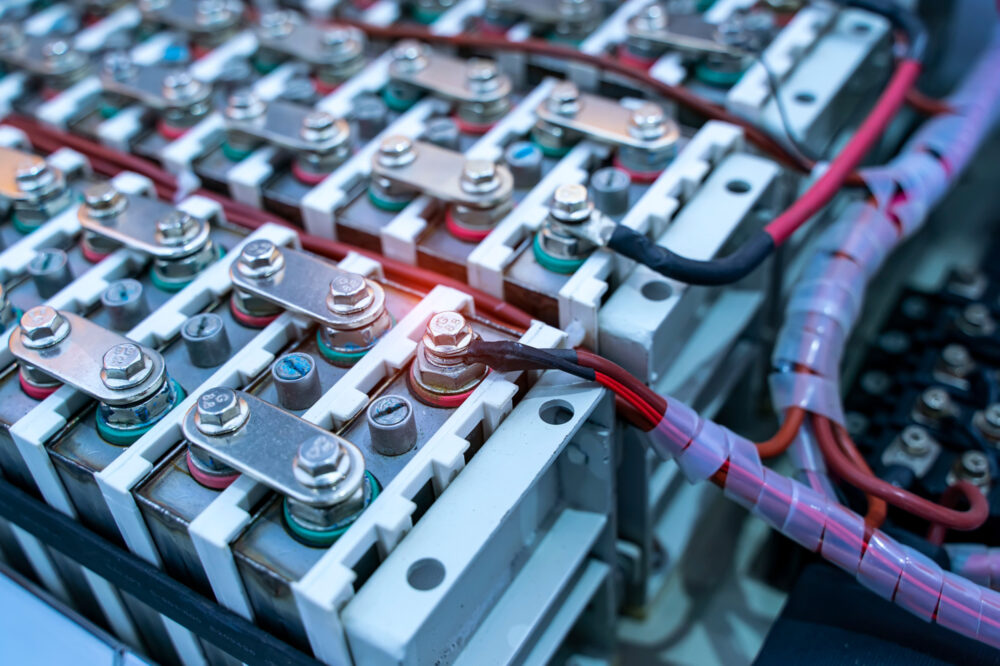

And the materials used in EV batteries are making a big difference.

Each EV battery contains up to 100 kg of anode graphite, making it the biggest component by weight.

Anode graphite accounts for 20% of the battery CO₂ footprint on average.

The global annual demand for batteries is growing exponentially:

SourceManufacturing this amount of anode graphite with conventional technology would produce major carbon emissions:

8 billion tons

That’s more than the annual emissions of every gasoline care on the planet.

With Vianode technology more than 90% of these emissions can be avoided.

SourceThe vision of Vianode is to push the carbon footprint of the EV battery industry towards zero.

We are building a highly scalable, circular value chain for anode graphite in Europe and North America, enabling cleaner EV batteries.

This is how we do it:

1. Raw material

Our starting point is carbon feedstock.

2. Closed furnace technology

Our proprietary closed furnace technology keeps emissions and energy consumption at a bare minimum.

3. Clean energy

Vianode powers its plants with clean energy.

4. Anode graphite

Our high-performance anode graphite has a 90% lower carbon footprint than graphite produced with conventional production methods. Currently, our footprint is 1.9 kg CO₂e/kg anode graphite (LCA 2024, Minviro). By 2030 we are aiming to reduce it to only 1 kg CO₂e/kg anode graphite.

5. Advanced material

We engineer anode graphite optimized for different requirements such as long range, fast charging, or a balanced combination of the two.

6. EV battery

Anode graphite is the biggest single component of an EV battery by weight, up to 100 kg/battery. On average, anode graphite makes up for 20% of the carbon footprint of an EV, but only around 10% of the cost.

7. Electric vehicles

To EV and battery manufacturers, replacing conventional anode graphite with sustainable anode graphite from Vianode is the most efficient way to cut battery emissions.

8. Infinite EVs

As production volumes increase, ensuring a resilient supply chain of battery materials is one of the challenges the EV industry is facing.

9. Recycling anode graphite

To close the loop on graphite production, Vianode recycles battery-grade anode graphite.

In 2040, we think recycled graphite will be one of the most in-demand battery anode materials. Our anode graphite cycle powers responsible growth - built to last, made to scale.