Anode graphite for the carbon neutral society

Batteries are essential to the energy transition, as the world is moving away from fossil fuels. Faced with global warming, our vision is to minimize the carbon footprint of battery and EV manufacturers.

We deliver the most efficient solution to reduce battery industry emissions

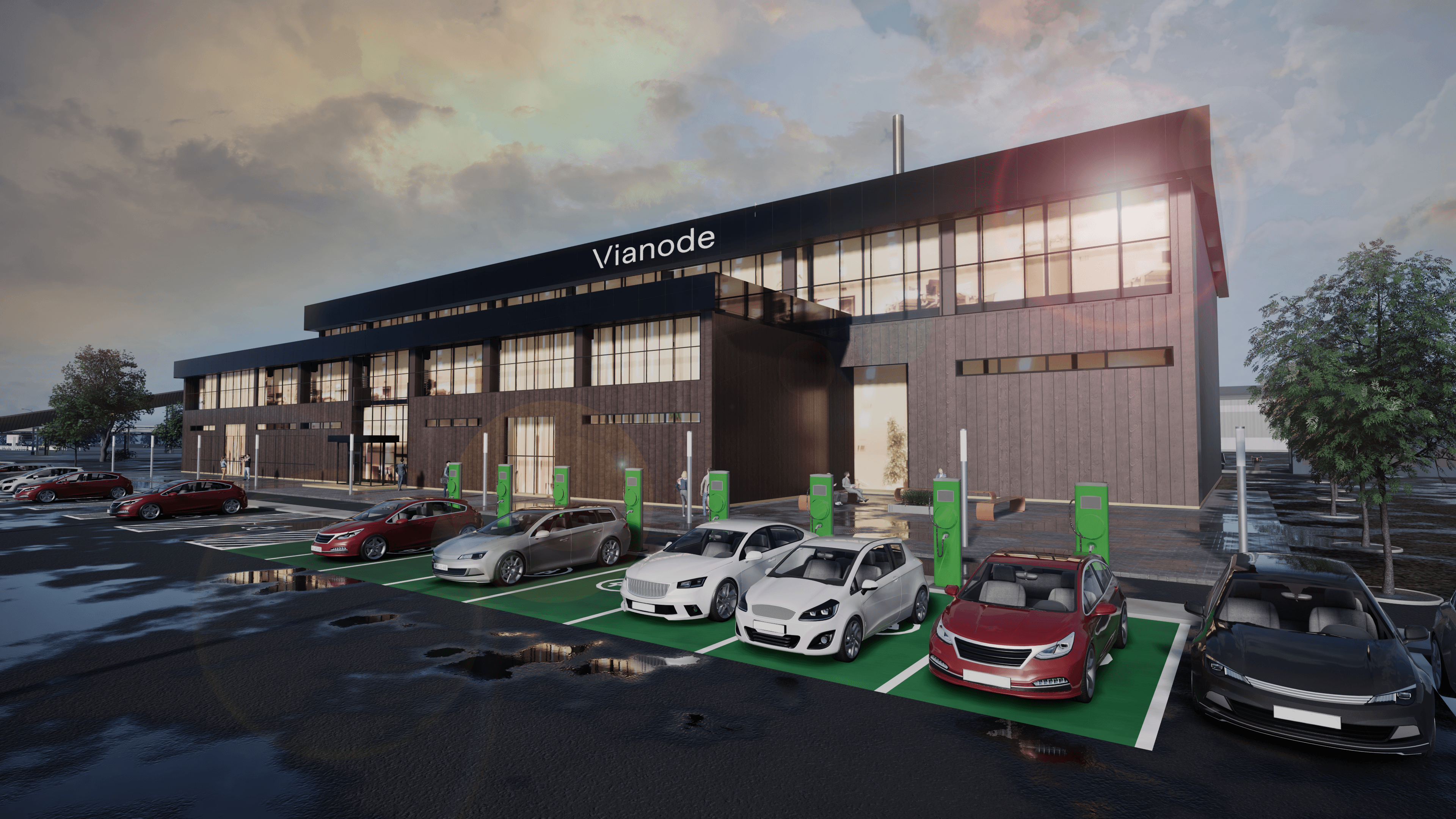

At Vianode, we are leading the transformation of creating a sustainable EV battery value chain. We empower battery and EV manufacturers to reduce their carbon footprint by replacing traditional, emission-heavy anode graphite with our innovative, high-performance anode graphite solutions.

Anode graphite is the biggest part of lithium-ion batteries by weight, but only a small percentage of the cost. Choosing Vianode graphite reduces the CO2 emissions of battery manufacturing, in the most efficient way.

Ambition

- At Vianode, it is our ambition to shape our industry while reducing the carbon footprint of synthetic graphite.

Via TWO

Discover our first large-scale production facility in Canada

Go to Via TWO

Vianode's Vision

Strategy

EV focus

Based on our strong industrial legacy and innovative anode graphite technology, Vianode is addressing the urgent need for decarbonisation. Transport is accountable for approximately 20% of global CO2 emissions. The shift from fossil fuel-powered vehicles to electric vehicles (EVs) is driving an estimated 30% yearly expansion in lithium-ion battery production from 2020 to 2030.

Market opportunity

Without synthetic graphite, there can be no lithium-ion EV batteries. In 2023, approximately 24% of the global anode material supply was made up of natural graphite while 74% was with synthetic graphite. Some OEMs rely up to a 100% on synthetic graphite for performance and safety reasons.

Sustainability leader

In 2030 Vianode aims to deliver a world leading carbon footprint of only 1 kg CO2 emission/kg high-performance, high-quality anode graphite for 3 million EVs annually. The current market average is 20 kg CO2/kg conventional anode graphite.

Objectives 2030

1million

EVs annually

2.0kg CO2/ kg

anode graphite

Roadmap and milestones

Management team

Get to know our management team

Meet our team

Our products

Our advanced anode graphite provides a solid foundation for customized product development and innovation.

Explore products